Replacing Legacy Radome Panels for Critical Infrastructure

Nav CAnada Case Study

Client Overview

NAV CANADA, a client since 2023, required replacement panels for large terrestrial radar radomes whose original manufacturer had gone out of business. Without readily available replacement parts, the infrastructure faced risks to operational continuity and RF performance. CCI was engaged to design, engineer, and manufacture custom replacement radome panels that matched the original geometry, met stringent environmental requirements, and ensured optimal RF transparency — all while under a tight timeline for turnaround and delivery.

The Challenge

The project presented several complex technical challenges:

The original manufacturing source was no longer available, and replacement panels could not be purchased off the shelf.

Panels needed to match the geometry precisely so they would bolt into existing radome structures without modification.

The replacement panels had to meet the original RF transparency specifications at operational frequencies.

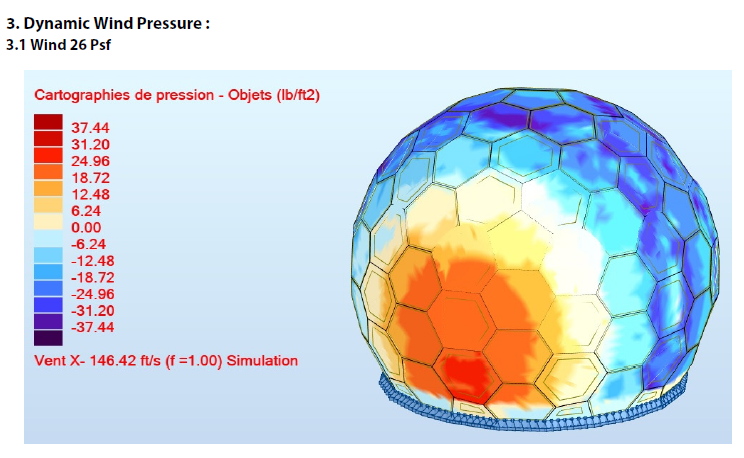

Panels also had to satisfy environmental specifications, including wind, snow, and ice loads typical of harsh operational settings.

CCI’s engineering team also identified that the original panel design included excessive adhesive putty between the foam core and fiberglass skins, which had a negative impact on RF transparency in actual use — a key performance concern that needed correction rather than replication.

Timeline

During this six-month period, engineering analysis, RF testing, tooling development, and manufacturing were conducted in parallel to meet delivery requirements while maintaining performance and quality standards.

Project Scope

Objective:

Design, engineer, and manufacture custom replacement radome panels for a legacy terrestrial radar system, ensuring full compatibility with existing infrastructure while meeting strict RF transparency and environmental performance requirements.

Scope of Work:

Reverse engineering of existing radome panels

Dimensional analysis and material evaluation

Custom tooling and mold fabrication

RF transparency analysis and optimization

Structural engineering verification for environmental loads

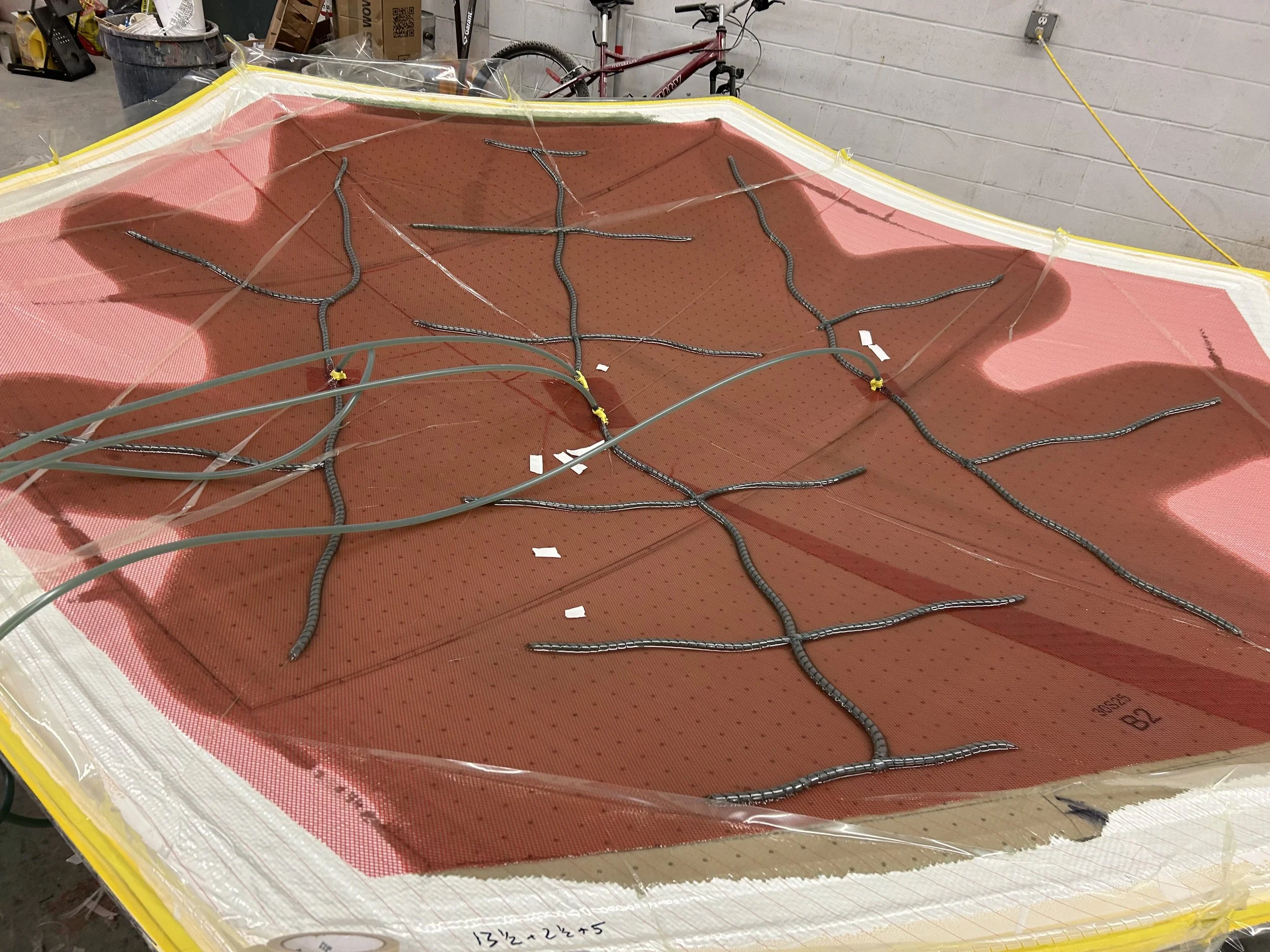

Composite panel manufacturing using vacuum infusion

Quality control, packaging, and delivery of finished panels

The Solution

CCI approached the project with a structured, engineering-driven methodology designed to resolve these challenges and deliver a high-performance, compatible solution.

Reverse Engineering and Material Analysis

CCI began by analyzing an original panel provided by the client:

Dimensional data captured through detailed measurement

Core sampling to identify material composition

Analysis of the foam core and fiberglass sandwich structure

This process informed the baseline design and surfaced non-optimal construction techniques in the original. CCI’s team determined that excess putty used in the original manufacturing, while perhaps passable in test conditions, would degrade RF transparency in real use.

Core sample of old panel

3d scanning inside radome

3d scan of old panel

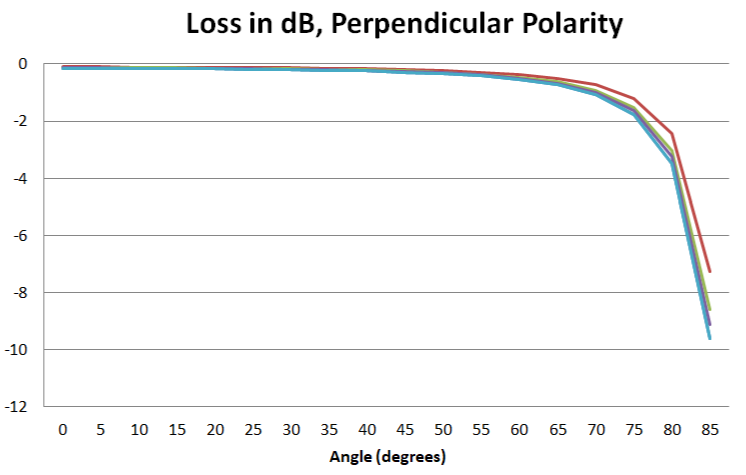

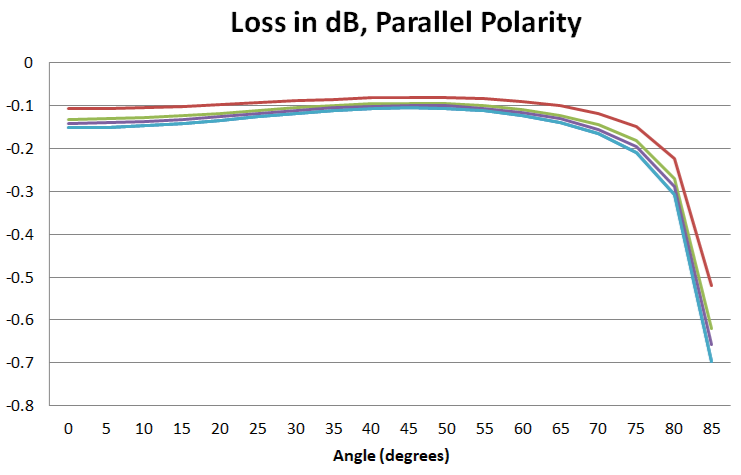

Output of our analysis tool: RF loss in dB vs angle of incidence

Optimized Radome Design & Vacuum Infusion

Once the structure was understood, CCI redesigned the radome laminate schedule for:

Improved RF transparency

Matched mechanical strength

Consistent manufacturing outcomes

Using vacuum infusion, CCI precisely controlled resin content and eliminated excess materials that could degrade RF performance. The foam core was secured without the need for excessive adhesives, preserving signal clarity and structural integrity.

Excerpt from Structural Engineering Report

CCI’s vacuum infusion process for precision composite panel fabrication

50-foot diameter terrestrial radome

30-foot diameter terrestrial radome

Radome Configurations:

Delivered 35 high-precision replacement radome panels

A dozen custom molds to accommodate multiple panel geometries

Production Output:

Services Applied

CCI delivered the following integrated services:

Dimensional reverse engineering of existing panels

Custom 3D scanning and tooling fabrication

Composite engineering and laminate optimization

Vacuum infusion composite manufacturing

RF performance analysis and validation

Structural analysis for environmental load compliance

Results and Key Learnings

CCI successfully delivered 35 high-precision replacement radome panels that:

Ensured compatibility with existing infrastructure

Met or exceeded original RF transparency specifications

Complied with environmental load requirements

Eliminated construction issues from legacy panel designs

Extended the expected operational life of the radomes

Custom tooling created for accurately reproducing original panel geometry.

We built a sample using the same resin vacuum infusion process that we would be using for production. This, and a sample cut from the original panel, were sent out for testing. Our panel is Sample 2, the original is Sample 1.

RF Performance Validation

RF performance comparison showing improved transparency with CCI panels.

Reverse engineering uncovers opportunities for performance improvement.

Rather than simply copying an outdated design, CCI identified material inefficiencies that were harming RF performance and corrected them.Precision manufacturing matters.

Vacuum infusion enabled consistent, high-quality composite panels that met both RF and structural specifications.Maintaining geometry is critical to system compatibility.

Panels that did not match original shapes would have required costly system redesigns.